History of IAQ

IAQ Global Offices

Starting from Malaysia, IAQ has swiftly expanded across continents, leveraging our expertise to support the specialized needs of hi-tech sectors. With a presence in key regions worldwide, IAQ’s comprehensive solutions have become integral in enhancing infrastructure and operations for various cutting-edge industries on a global scale.

Countries

Offices

Malaysia

Singapore

China

Morocco

Poland

France

Sweden

Legacy in Progress IAQ Company Journey

In 1994, IAQ was born as a Cleanroom Specialist. Since then, with steadfast commitment and pioneering spirit, IAQ have evolved and thrived, shaping the future of our field, expanding our global footprint as Your Total Facility Solutions Provider.

IAQ was founded in 1994 as a Cleanroom Specialist founded by Ir. Tiew Soon Aik. IAQ humble journey begins out of a small office, armed with little more than a blueprint and unrelenting spirit and determination to provide exceptional service. Undertaking project with a commitment to excellence, each project serves as steppingstone, propelling us forward in both expertise and reputation.

Our first project in China is serving our client for construction of cleanroom, Mechanical and Electrical (M&E) works, and all utilities services. Built-up area for this project is 25,000 sqm. As a bilingual company, IAQ had the opportunity to serve multi-national client investing in China during the dot com boom, where surplus of foreign chip company was investing in China.

Project involve design Class 1K, 10K and 100K Cleanroom, with Mechanical and Electrical and Process Utility works with built-up area of 7000 sqm. The facility was built for LCD production.

Project involve design Class 1K, 10K and 100K Cleanroom, with Mechanical and Electrical works with built-up area of 5000 sqm. The facility was built for Microdrive production.

Project involve design Class 10K Cleanroom with M&E and Utility services with total built up area of 5000 sqm. The facility was built for CDR and DVDR production.

Cleanroom and Air-conditioning & Mechanical ventilation (ACMV) System installation with contract value for this project is RM4 million.

Class 10 ~ Class 100K Cleanrooms, Architectural works, HVAC Works, Electrical Works, BMS System, Fire Protection System, Plumbing, Utilities System for built-up area of 3000 sqm. For this project, IAQ secured RM22 million contract value.

IAQ set up an branch office in Poland to provide, Engineering, Procurement, Construction, and Commissioning (EPCC) services to our client. This project cover cleanroom architecture, mechanical & electrical system.

With the rise of data storage demand, higher capacity requirement, HDD manufacturing expansion comes into play. IAQ emerged as a beacon of expertise in cleanroom facility solutions. Our unwavering dedication to purity, precision, and innovation played an instrumental role in shaping the microcosmic world where data storage was meticulously crafted.

At IAQ, we are the proud of our achievement that sets us apart from our peers – we successfully build and delivered Class 10 cleanrooms to our client. We have harnessed cutting-edge technologies and meticulous design to deliver the best for WD.

IAQ expands our global footprint once again, from Poland to France through customer’s recommendation, we resolved Client’s production challenges and improving efficacy. Our success in identifying and addressed facility bottleneck through FMEA analysis, boosts Client’s production efficiency and operational productivity, gaining their trust and confidence. Earning IAQ new project in Europe undertaking MEP GC role for cleanroom facilities construction project in France. Our expertise, dedication to excellence, and reputation as a Total Facility Solutions Provider are evident in the successful outcome.

IAQ's journey of excellence involves conquering challenges and embracing new horizons. Enthralled towards a new challenge, coupled with our pursuit of excellence we constructed a Class 1 cleanroom facility for our client in Ipoh, Malaysia with built-up area of 14,000sqm. The turnkey project goes beyond construction, focusing on creating an environment where purity reaches its zenith. This marks another milestone, our ability to overcome obstacles with innovative approaches fosters fresh insights, nurturing a space for innovation to flourish.

Following our client’s footsteps, we too expanded our business to Morocco. Partnership with our clients goes beyond business, showcasing our excellence in building cleanroom facilities and providing Mechanical, Electrical and Plumbing (MEP) and hookup works in Morocco.

Built-up area of 2,880 sqm of electronic manufacturing plant involving architectural, Air-Conditioning & Mechanical Ventilation system & Fire Protection system for Cleanroom of Class 1K. We secured SGD 4.7 million contract value for this project.

Completed Air-conditioning & Mechanical Ventilation Services for built-up area of 3,100 sqm. IAQ secured a contract value of RM6.5 million for this project.

Awarded for this project to built a 6,380 sqm cleanroom area including Architectural work, Mechanical, Air-conditioning System, Electrical System, Process Utilities and Testing & Commissioning works. Contract value for this project is RM8.4 million.

In 2013, IAQ ventured into energy industry, securing RM310 million contract as mainIn 2013, IAQ ventured into energy industry, securing RM310 million contract as main contractor for our client DCS Plant, Malaysia's largest district cooling plant. This project serves as affirmation to IAQ's capabilities and commitment to a greener, more sustainable future. Centralised chilled water was supplied to 56,000 parties in the KLCC area without interruption and we achieved zero Lost Time Injury (LTI) throughout project completion. IAQ secured a contract value of RM 310 million for both Phase 1 & Phase 2 construction, with the addition of 25-year maintenance service contract, as a result of our commitment and achievement project delivery. IAQ's construction and engineering expertise takes on a new height, laying foundations for a state-of-the-art district cooling system plant that promotes efficiency and sustainability. contractor for our client DCS Plant, Malaysia's largest district cooling plant. This project serves as affirmation to IAQ's capabilities and commitment to a greener, more sustainable future. Centralised chilled water was supplied to 56,000 parties in the KLCC area without interruption and we achieved zero Lost Time Injury (LTI) throughout project completion. IAQ secured a contract value of RM 310 million for both Phase 1 & Phase 2 construction, with the addition of 25-year maintenance service contract, as a result of our commitment and achievement project delivery. IAQ's construction and engineering expertise takes on a new height, laying foundations for a state-of-the-art district cooling system plant that promotes efficiency and sustainability.

Our services includes Construction, Completion, Testing & Commissioning , Care and Maintenance for Mechanical & Electrical Works Package securing a RM45 million contract value for this project.

IAQ was awarded with RM122 million contract for this project providing Engineering, Procurement, Construction and Management (EPCM) with GMP contract model for 43,000 sqm of cleanroom area.

IAQ secured RM34 million contract, providing Engineering, Procurement, Construction and Commissioning (EPCC) services for our client for Class 100 cleanroom works. Our client is Malaysia’s National Wafer Fab plant, the brainchild of Prime Minister Tun Dr. Mahathir, and vision to develop a local semiconductor chip plant to serve as the foundation and aspiration for Malaysia to evolve into a developed nation. And we are honoured to contribute.

IAQ's trajectory span across various industries, showcasing agility, inventive spirit, and dedication to excellence. The pharmaceutical venture in Kelantan involves building a Grade D GMP Facility with a Class 10k Cleanroom system, Mechanical, Electrical and Plumbing (MEP) across 5,600 sqm, securing a RM54 million contract. This marks a new steppingstone in IAQ's evolution, underscoring the company's commitment to excellence in diverse fields.

Secured RM1.6 million contract with Microdrive client for their new project, upgrading Storage & Shipping facility for environment control.

IAQ was awarded with RM3.3 million contract for chiller plant upgrading works for a hospital.

In 2020, IAQ was awarded a contract to serve our client in Sweden, focusing on Architecture, Structural and Dry Room facility for their Gigafactory. This milestone expands IAQ's market reach into the EV battery industry, in line with our CEO’s vision to establish leadership in hi-tech facility engineering and construction for global clients, whilst meeting international standards. The global push for EV batteries aligns with IAQ's commitment to combat climate change, contributing to the electrifying revolution.

Awarded with a RM215 million contract to construct a Testing & Probe Assembly Plant that is GBI certified. Faced with COVID-19 restrictions and headwind, IAQ once again delivers, successfully overcome construction delays, and delivered the project ahead of schedule. Experiences we accumulated pushes IAQ to the forefront of Green Building construction know-how.

Sheer scale and complexity undertaken by IAQ for our client in Kulim, Kedah goes beyond receiving recognition; it stands as a strong validation to unparalleled capability not only to accomplish task but also to revolutionize and excel on a grand scale. Securing a RM900 million mega project elevates IAQ to a league of its own, crafting history and building aspirations. This achievement is a reflection of IAQ dedication of pushing boundaries, redefining possibilities, and setting new benchmarks.

Known for expertise in cleanroom facilities for semiconductor, energy, pharmaceuticals, and EV battery sectors, IAQ now ventures into the realm of data centres. Our first step into this segment, begin as PCC contractor for our client's data centre, providing HVAC (Wet) Package services. IAQ is proud to be part of this new journey with a RM24 million contract, IAQ envisions the facilities that we build today houses the technology of tomorrow in the booming data centre industry.

New collaboration with our previous partner has marks another significant milestone for IAQ. This is a Design & Build contract model, where our scope covers, Civil, Structural and Architectural (CSA), Mechanical and Electrical, Instrumentation and Process System and Class 100 to Class 10K Cleanroom.

IAQ Global Offices

Starting from Malaysia, IAQ has swiftly expanded across continents, leveraging our expertise to support the specialized needs of high-tech sectors. With a presence in key regions worldwide, IAQ’s comprehensive solutions have become integral in enhancing infrastructure and operations for various cutting-edge industries on a global scale.

1994

Legacy in Progress: IAQ Company Journey

In 1994, IAQ was born as a Cleanroom Specialist. Since then, with steadfast commitment and pioneering spirit, IAQ have evolved and thrived, shaping the future of our field, expanding our global footprint as Your Total Facility Solutions Provider.

2000

China’s economic growth and dot com boom!

Our first project in China is serving our client for construction of cleanroom, Mechanical and Electrical (M&E) works, and all utilities services. Built-up are for this project is 25,000 sqm. As a bilingual company, IAQ had the opportunity to serve multi-national clients investing in China during the dot com boom, where surplus of multi-national chip company was investing in China.

2003

Microdrive Production in China!

Design, cleanroom, M&E, Class 100K, 10K, 1K with built-up area of 5000m2. The facility was built for Microdrive production.

2004

CDR and DVDR manufacturing facility, in China!

Design, Cleanroom, M&E, Utility, Class 10K with built-up area of 5000m2. The facility was built for CDR and DVDR production.

2005

Pharmaniaga Lifescience

Cleanroom installation (internal wall partitions, suspended ceiling, floor furnishes & furniture), Air-conditioning & Mechanical ventilation System. Contract value for this project is RM4million.

2006

Cleanroom Project for Client in Kuala Lumpur, Malaysia

Class 10 ~ Class 100K Cleanrooms, Architectural works, HVAC Works, Electrical Works, BMS System, Fire Protection System, Plumbing, Utilities System for built-up area of 3000m2. For this project, IAQ secured RM22 million contract value.

2007

From Asia into Europe, IAQ embark new journey in Poland!

IAQ set up an office branch in Poland to provide, Engineering, Procurement, Construction, and Commissioning (EPCC) services to our client. This project cover cleanroom architecture, mechanical & electrical system.

2008

Data Storage Boom: Surging in demand for HDD! Cleanroom Built: Class 10

With the rise of data storage demand, with higher capacity requirement and development, HDD manufacturing expansion comes into play. IAQ emerged as a beacon of expertise in cleanroom facility solutions. Our unwavering dedication to purity, precision, and innovation played an instrumental role in shaping the microcosmic world where data storage was meticulously crafted.

At IAQ, we are the proud bearers of a capability that sets us apart from our peers– the ability to build Class 10 cleanrooms are unparallel. We have harnessed cutting-edge technologies and meticulous design to deliver the best for Western Digital.

2008

Building a strong presence: IAQ continues to thrive in Europe with another project in France!

IAQ expands our global footprint once again, from Poland to France through customer’s recommendation, we resolved Client’s production challenges and improving efficacy. Our success in identifying and addressed facility bottleneck through FMEA analysis, boosts Client’s production efficiency and operational productivity, gaining their trust and confidence. Trust and confidence gained, earned IAQ new project in Europe undertaking MEP GC role for cleanroom facilities construction project in France. Our expertise, dedication to excellence, and reputation as a Total Facility Solutions Provider are evident in the successful outcome.

2009

Highest classification of cleanroom built! Class 1

IAQ’s journey of excellence involves conquering challenges and embracing new horizons. Enthralled towards a new challenge, coupled with our pursuit of excellence we constructed a Class 1 cleanroom facility for our client in Ipoh, Malaysia with built-up area of 14,000sqm. The turnkey project goes beyond construction, focusing on creating an environment where purity reaches its zenith. This marks another milestone, our ability to overcome obstacles with innovative approaches fosters fresh insights, nurturing a space for innovation to flourish.

2009

IAQ has set a new footprint in Morocco!

Following our client’s footsteps, we too expanded our business to Morocco. Partnership with our clients goes beyond business, showcasing our excellence in building cleanroom facilities and providing Mechanical, Electrical and Plumbing (MEP) and hookup works in Morocco.

2010

Electronics Manufacturing Plants in Singapore.

Built-up of 2880m2 of electronic manufacturing plant involving architectural, Air-conditioning & mechanical ventilation system & Fire protection system for cleanroom of class 1K. Secure SGD 4.7 million contract value for this project.

2011

Life science project for client located at Selangor.

Sub-contract for Air-conditioning & Mechanical Ventilation Services for built-up area of 3100m2. IAQ secured a contract value of RM6.5 million for this project.

2012

Cleanroom Installation for semiconductor manufacturing Plant in Shah Alam

Awarded for this project to built a 6380m2 cleanroom area including architectural work, mechanical, Air–conditioning System, Electrical System, Process Utilities and Testing & Commissioning works. Contract value for this project is RM8.4 million.

2013

IAQ Venturing into Energy Industry for Malaysia’s Largest District Cooling system.

In 2013, IAQ ventured into energy industry, securing RM 310 million contract as main contractor for our client DCS Plant, Malaysia’s largest district cooling plant. This project serves as affirmation to IAQ’s capabilities and commitment to a greener, more sustainable future. Centralised chilled water was supplied to 56,000 parties in the KLCC area without interruption and we achieved zero Lost Time Injury (LTI) throughout project completion. IAQ secured a contract value of RM 310 million for both Phase 1 & Phase 2 construction, with the addition of 25-year maintenance service contract, as a result of our commitment and achievement project delivery. IAQ’s construction and engineering expertise takes on a new height, laying foundations for a state-of-the-art district cooling system plant that promotes efficiency and sustainability.

2014

IAQ contribution in providing MEP services for infrastructure industry

Mechanical & Electrical Works Package 5 which forms part of the main sub-contract for the construction, completion, Testing, Commissioning & care & maintenance of the works. IAQ Secure a RM45 million contract value for this project.

2015

Semiconductor Backend (Test & Assembly) Facility

IAQ was awarded a RM122 million contract value for this project where IAQ scope of works is Engineering, Procurement, Construction and Management (EPCM) for GMP works for a ~43,000m2 of cleanroom area.

2016

IAQ contributed as contractor for local semiconductor chip plant.

IAQ secured RM34 million contract, providing Engineering, Procurement, Construction and Commissioning (EPCC) services for our client for class 100 cleanroom works. Our client is Malaysia’s Wafer Fab plant, the brainchild of Prime Minister Tun Dr. Mahathir, and vision to develop a local semiconductor chip plant to serve as the foundation and aspiration for Malaysia to evolve into a developed nation. And we are honoured to contribute.

2017

Penetrating Pharmaceutical Industry as Cleanroom Specialist!

IAQ’s trajectory spans various industries, showcasing agility, inventive spirit, and dedication to excellence. The pharmaceutical venture in Kelantan involves building a Grade D GMP Facility with a Class 10k cleanroom system, Mechanical, Electrical and Plumbing (MEP) across 5,600 sqm, securing a RM54 million contract. This marks a new steppingstone in IAQ’s evolution, underscoring the company’s commitment to excellence in diverse fields.

2018

Architectural, Mechanical and Electrical Upgrading Works

Secured a RM1.6 million contract value again for one of our previous clients for the upgrading project of Store & Shipping facility to control environment facility.

2019

Chiller Plant Upgrading Works

IAQ was awarded for chiller plant upgrading works for a hospital with contract value of RM3.3 million.

2020

Another First Step! Into the age of EVs.

In 2020, IAQ was awarded a contract for one of our clients Gigafactory in Sweden, focusing on architectural structure and dry room facility. This milestone expands IAQ’s market reach into the EV battery industry, marking a new milestone for the company in line with our CEO’s vision to establish leadership in hi-tech facility engineering and construction for global clients, whilst meeting international standards. The global push for EV batteries aligns with IAQ’s commitment to combat climate change, contributing to the electrifying revolution.

2021

Green Building Index Building!

Awarded with a RM 215 million contract to construct a testing & probe assembly plant meeting GBI index. Faced with COVID-19 restrictions and headwind, IAQ once again delivers, successfully overcame construction delays, and delivered the project ahead of schedule. Experiences we accumulated pushes IAQ to the forefront of Green Building construction know-how.

2022

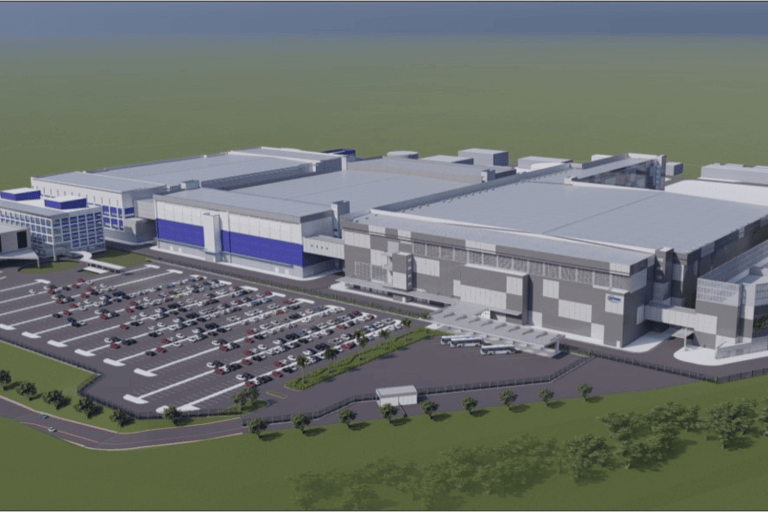

IAQ Solutions Mega Project Wafer Fab Expansion In Kulim

Sheer scale and complexity undertaken by IAQ for our client in Kulim, Kedah goes beyond receiving recognition; it stands as a strong validation to unparalleled capability not only to accomplish task but also to revolutionize and excel on a grand scale. Securing a RM900 million mega project elevates IAQ to a league of its own, crafting history and building aspirations. This achievement is a reflection of IAQ dedication of pushing boundaries, redefining possibilities, and setting new benchmarks.

2022

Unveiling the Future – IAQ Breakthrough into Data Centre!

Known for expertise in cleanroom facilities for semiconductor, energy, pharmaceuticals, and EV battery sectors, IAQ now ventures into the realm of data centres. Our first step into this segment, begin as PCC contractor for our client’s data centre, providing HVAC (Wet) Package services. IAQ is proud to be part of this new journey with a RM24 million contract value, IAQ envisions the facilities that we built today housing the technology of tomorrow in the booming data centre industry.

2023

Design & Build – Wafer Fab Expansion in Kuching, Sarawak.

New collaboration with our previous partner has marks another significant milestone for IAQ. One of the projects where IAQ involve on the entirety of the process with design & build contract, our scope covers, Civil, Structural and Architectural (CSA), Mechanical and Electrical, Instrumentation and Process System and Class 100 Cleanroom.