EPCM (Engineering, Procurement, Construction Management)

EPCC (Engineering, Procurement, Construction, Commissioning)

Energy Facility Management

IAQ oversee project from start to finish, ensuring efficient planning, resources, and execution. Consultancy provides expert design insight, constructability, schedule planning and cost management throughout project lifecycle.

Our EPCC services take clients from conception to operation to completion and maintenance. We manage every aspect, from initial design to commissioning, ensuring that client in hi-tech industries can bring their visions to life.

Sustainability and efficiency are at the forefront of modern industries. We specialize in energy audit, energy management solutions, helping clients optimize their operations while reducing their carbon footprint, in line with our ESG commitment.

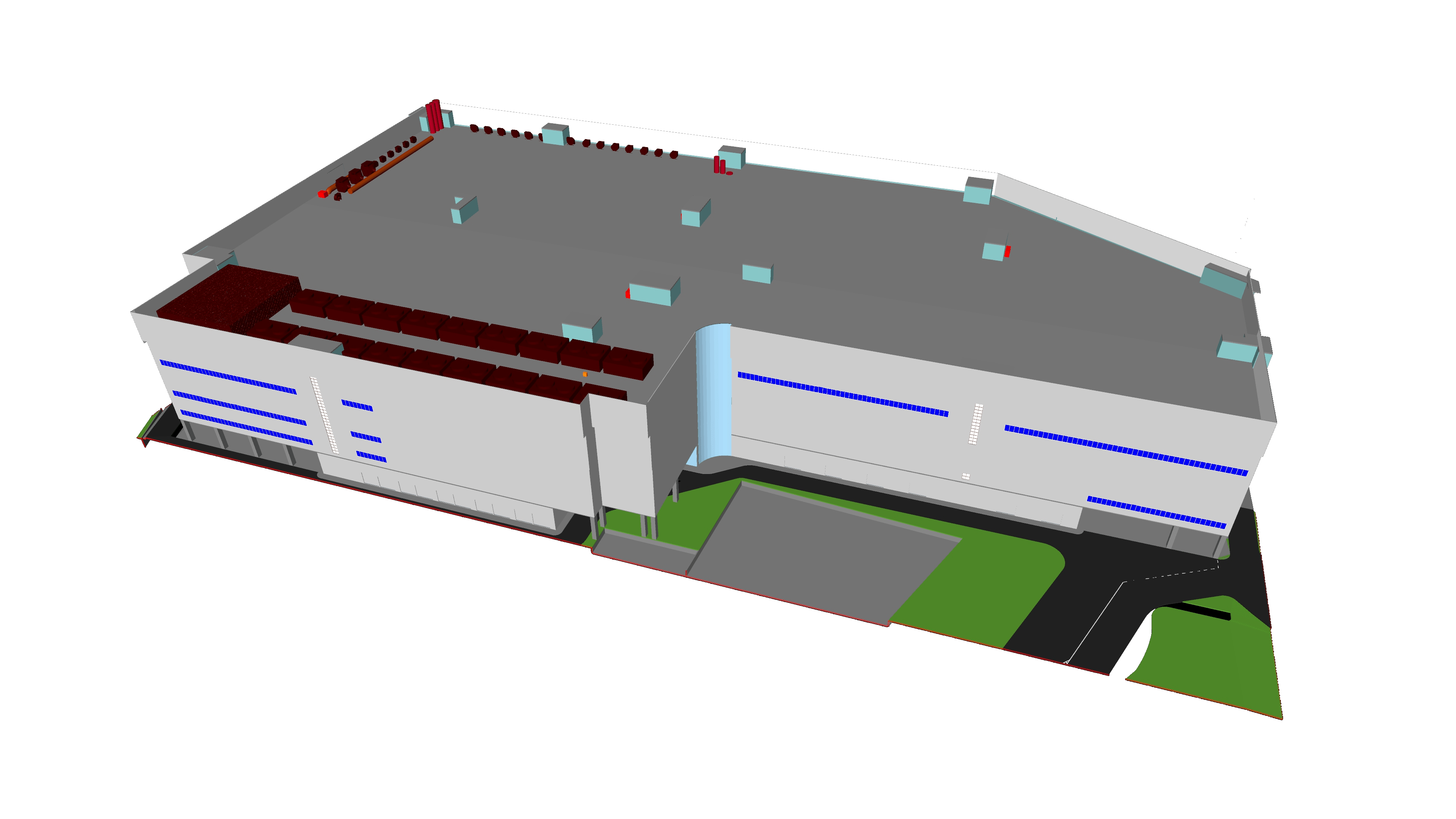

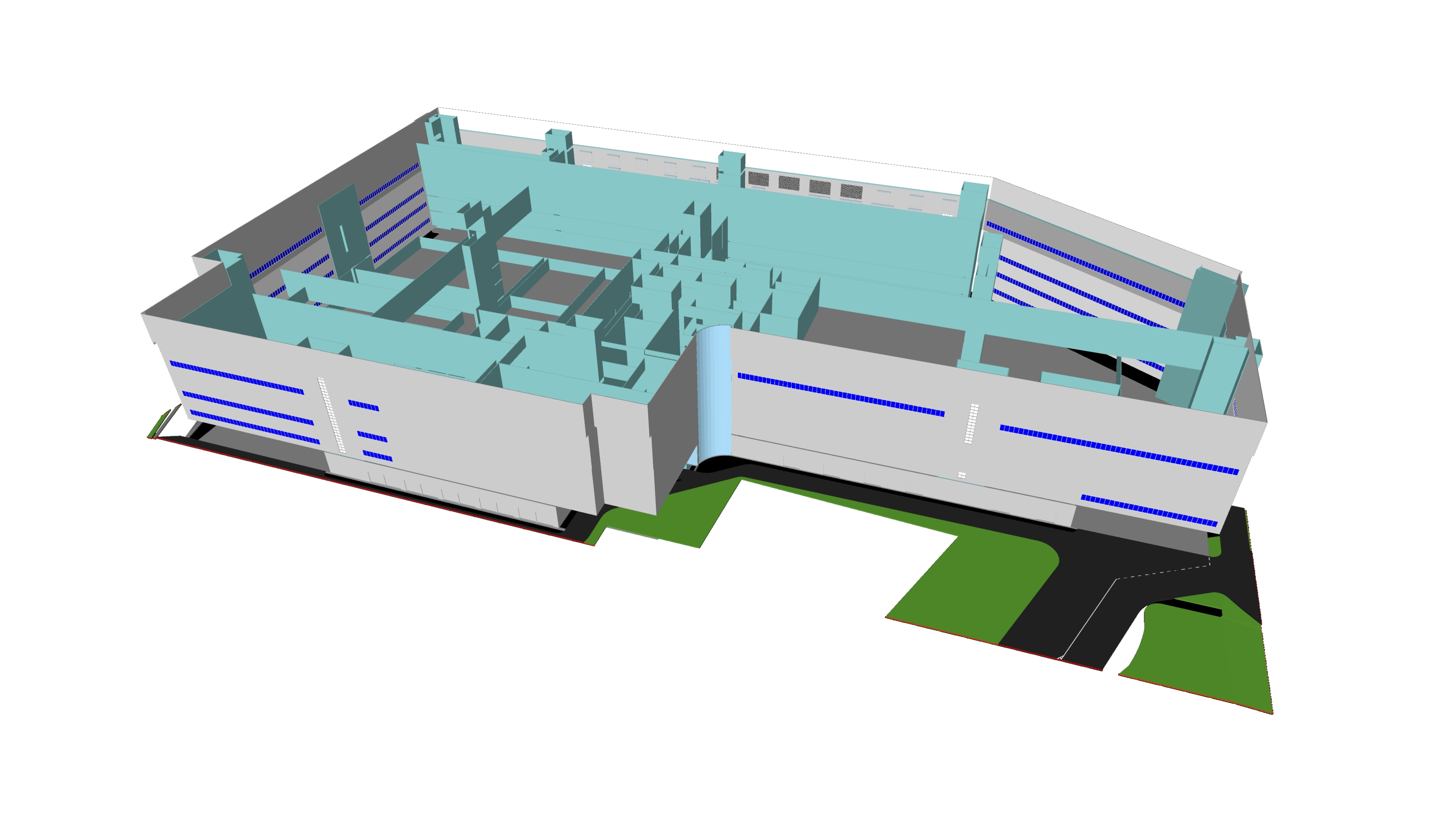

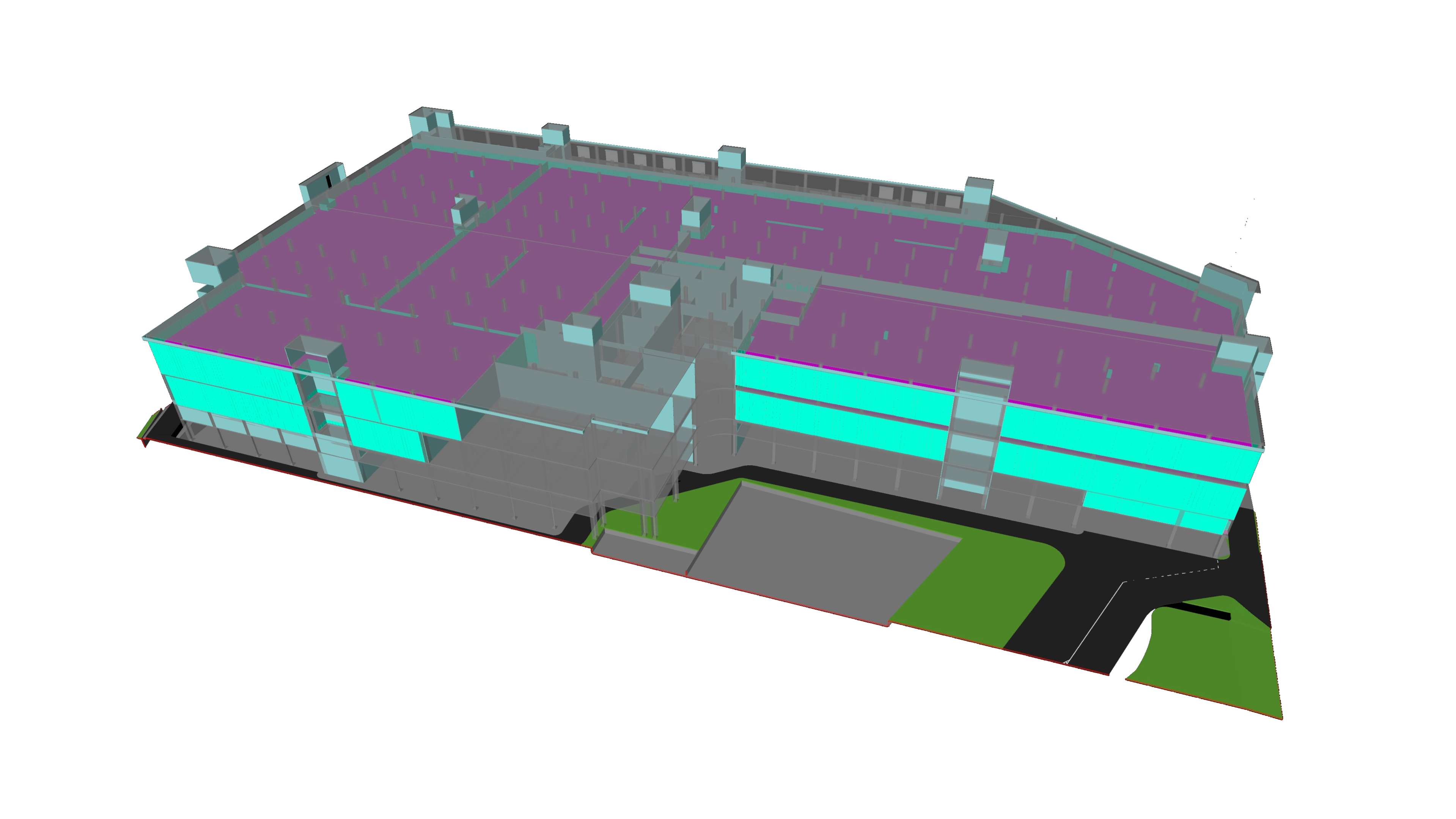

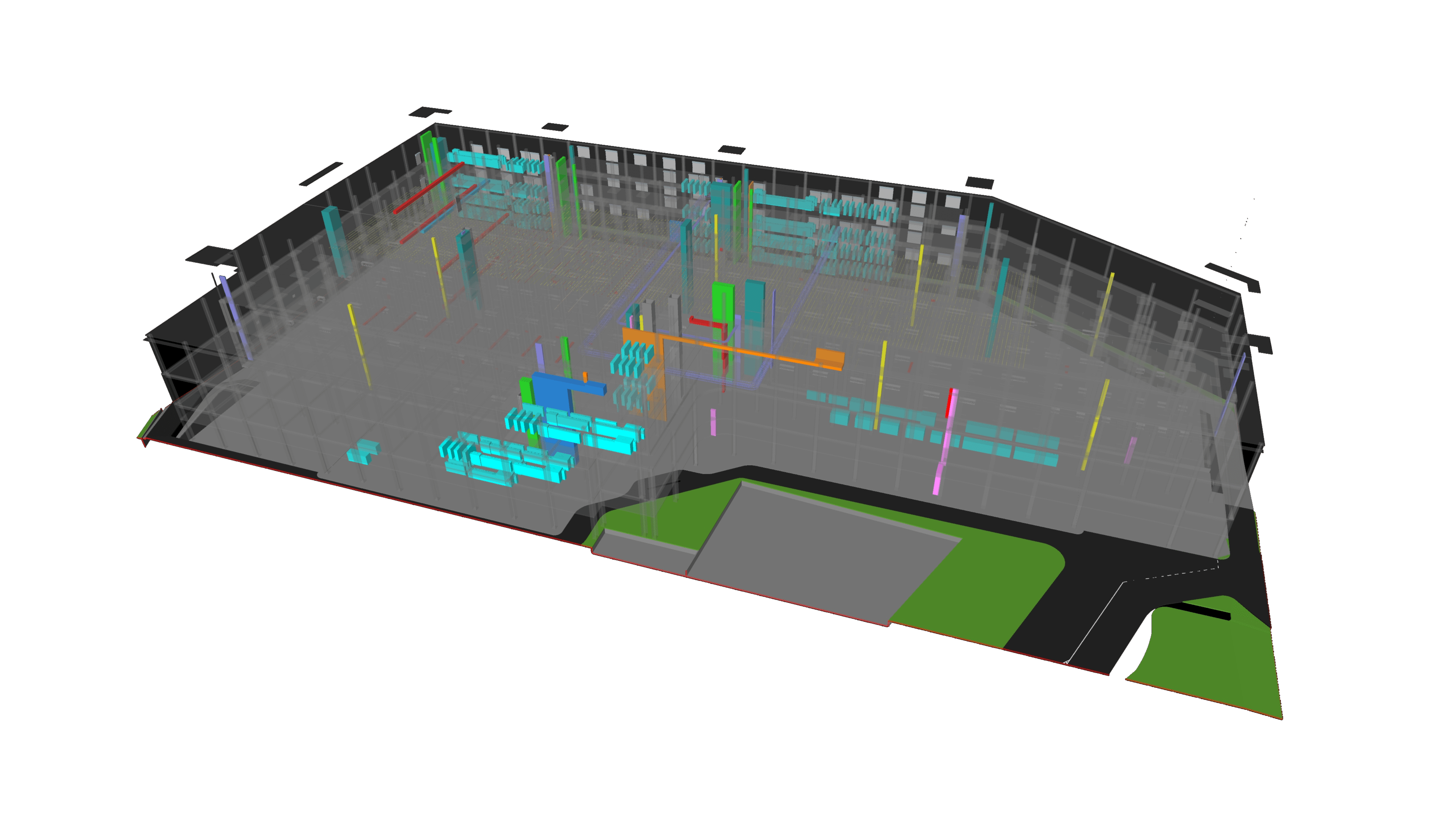

Elevating project with our holistic approach to construction. Unlocking excellence in high efficiency building design, our services go beyond the blueprint. From architectural finesse to meticulous tools hookup, we are committed to delivering comprehensive solutions for crafting cutting-edge facilities. With a proven track record, IAQ stands tall in unravelling complex challenges across diverse industries.

Creating layout that optimize cleanroom functionality, ensuring the controlled environment necessary for the industries includes specifying materials and finishes that meet stringent cleanliness standard, designing specialized ventilation and filtration systems. The goal is to create a space to comply to the strict cleanliness criteria, supporting precision manufacturing processes by minimizing the presence of particles that could compromise product quality.

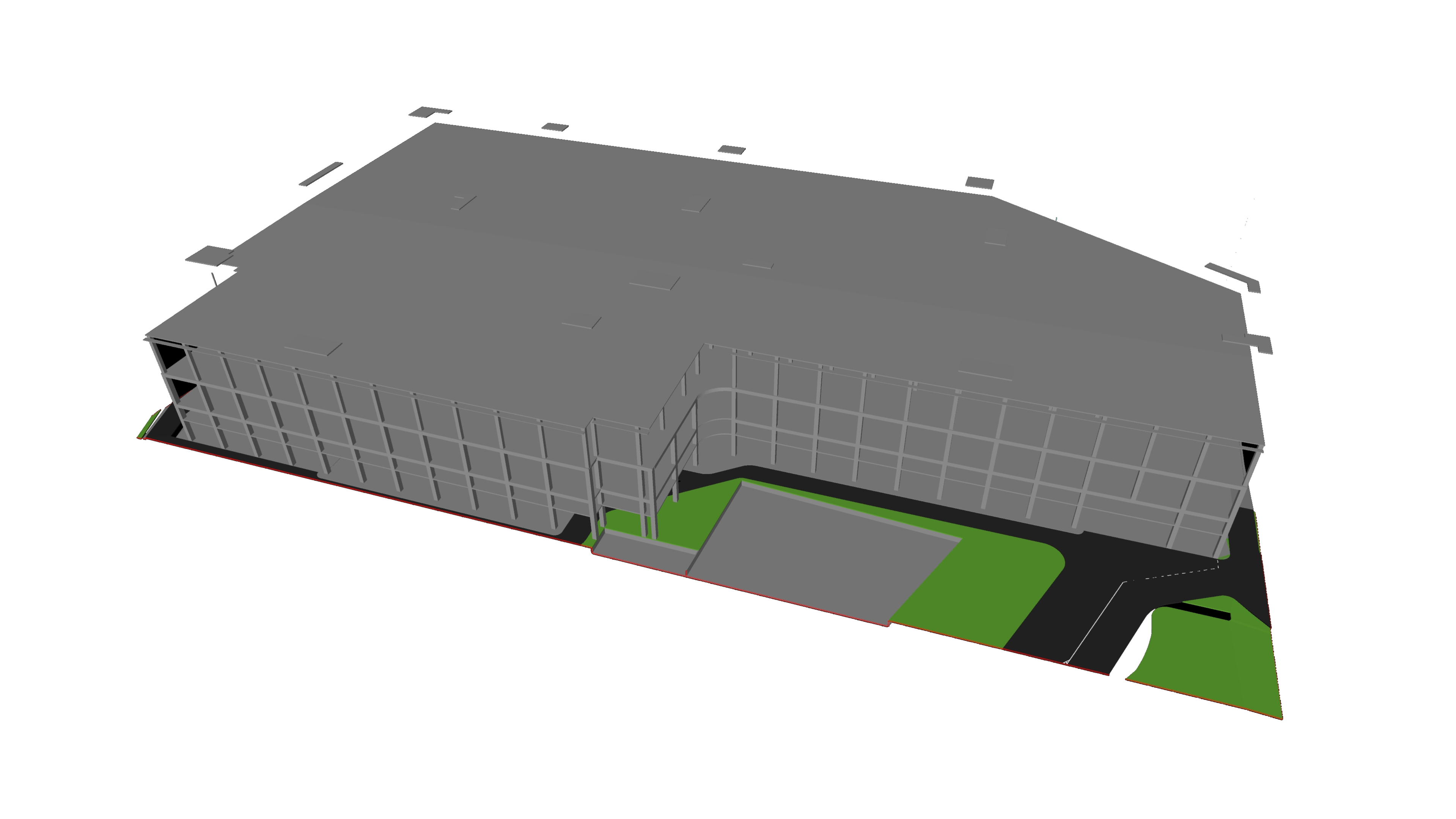

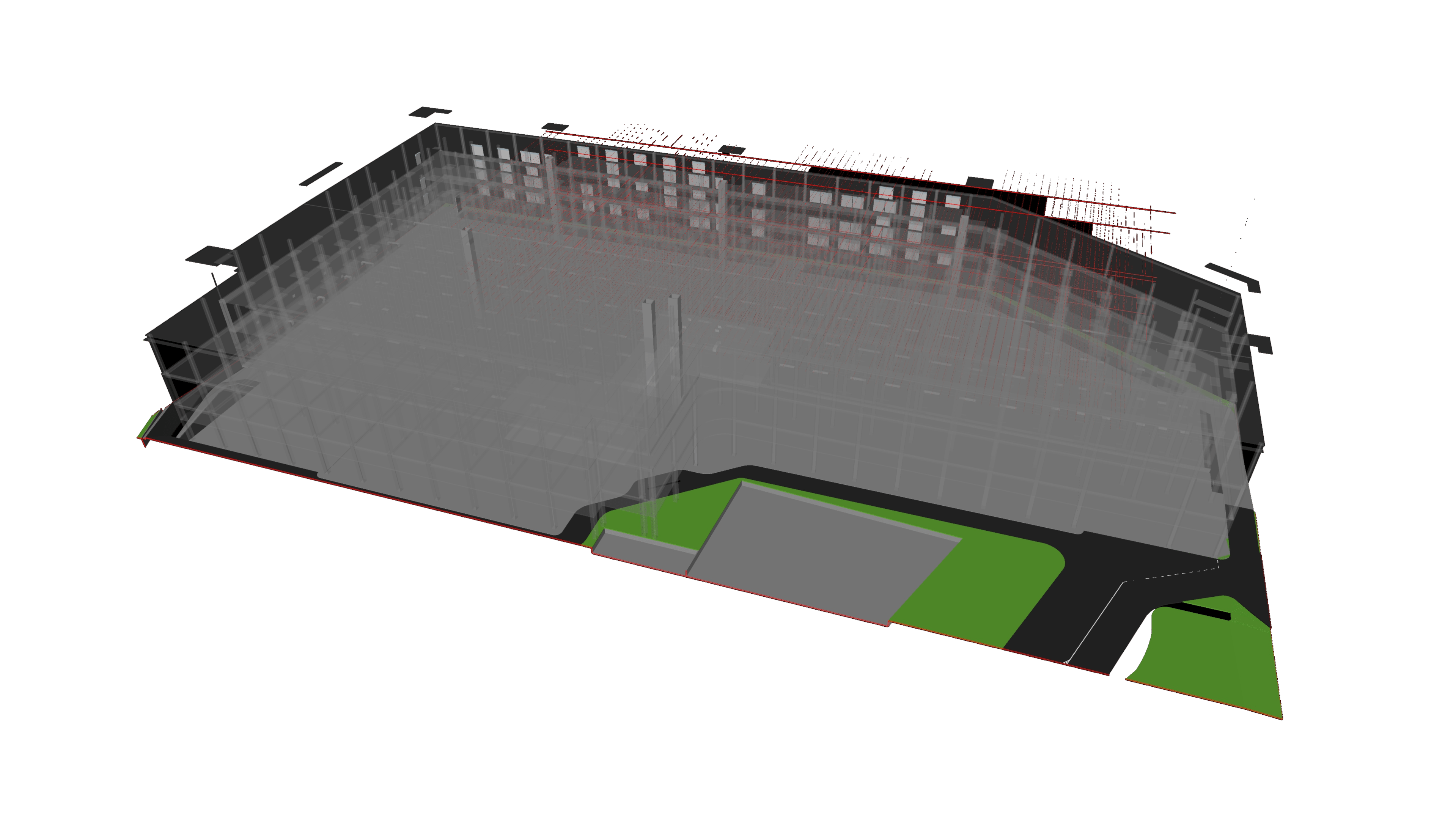

Civil and structural engineers work to create robust and efficient structures that can withstand the specific demands of industrial operations. This includes planning and executing the layout, foundations, framing and other structural elements in compliance to the safety standards and accommodate the specific needs of industrial equipment and processes.

Cleanroom system implementation is to maintain controlled environment with extremely low levels of airborne contaminants. Focus on creating specialized spaces within industrial facilities, such as those used in semiconductor manufacturing or pharmaceutical production, where precision and cleanliness are paramount. Designing advanced ventilation and filtration systems, specifying materials that meet stringent cleanliness standard and ensuring the controlled condition required for the industry.

Implementation of ACMV systems is to maintain optimal indoor environmental conditions within the facility tailored to the specific requirement of industrial settings. Designing and installing systems that regulate temperature, humidity, and air quality by integrating energy-efficient solutions, providing effective climate control while minimizing environmental impact.

HT (High Tension) and LV (Low Voltage) Electrical system involves the comprehensive design, installation and maintenance of electrical systems catering to both high-tension components for larger-scale power distribution and low voltage components for everyday electrical requirements. This system includes the design of wiring layouts, distribution panels and other electrical infrastructure, ensuring the safety and efficient supply throughout the industrial facility.

To create an optimized utility infrastructure that meets the needs of industrial operations by planning and implementing the infrastructure for utilities such as water, steam, gas, and other essential services required for manufacturing process. Ensure reliable supply distribution, and efficient use of these utilities, is within our capabilities to ensure overall efficiency and functionality of the facility.

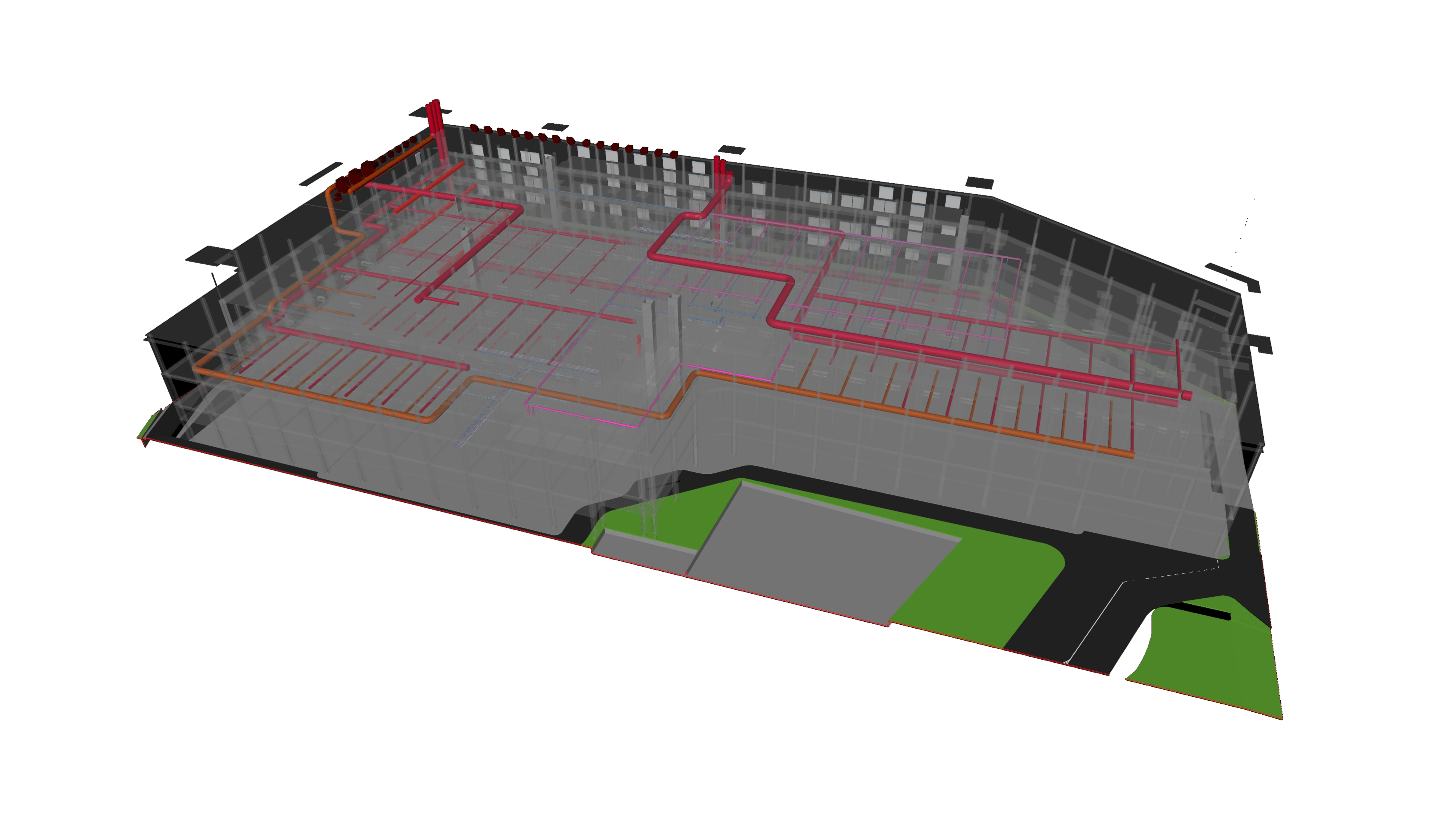

Fire protection system is design to prevent and manage fire risks within the facility. Focus on creating comprehensive solutions that safeguards both people and facility by integrating fire detection, alarm, and suppression systems. Collaborated with the authority to ensure that the fire protection system complies with the safety codes and standards.

Lorem ipsum dolor sit amet, consectetur

Lorem ipsum dolor sit amet, consectetur

Lorem ipsum dolor sit amet, consectetur

Lorem ipsum dolor sit amet, consectetur

Lorem ipsum dolor sit amet, consectetur

Lorem ipsum dolor sit amet, consectetur

Lorem ipsum dolor sit amet, consectetur

Lorem ipsum dolor sit amet, consectetur

Elevating project with our holistic approach to construction. Unlocking excellence in high efficiency building design, our services go beyond the blueprint. From architectural finesse to meticulous tools hookup, we are committed to delivering comprehensive solutions for crafting cutting-edge facilities. With a proven track record, IAQ stands tall in unravelling complex challenges across diverse industries.

Creating layout that optimize cleanroom functionality, ensuring the controlled environment necessary for the industries includes specifying materials and finishes that meet stringent cleanliness standard, designing specialized ventilation and filtration systems. The goal is to create a space to comply to the strict cleanliness criteria, supporting precision manufacturing processes by minimizing the presence of particles that could compromise product quality.

Civil and structural engineers work to create robust and efficient structures that can withstand the specific demands of industrial operations. This includes planning and executing the layout, foundations, framing and other structural elements in compliance to the safety standards and accommodate the specific needs of industrial equipment and processes.

Cleanroom system implementation is to maintain controlled environment with extremely low levels of airborne contaminants. Focus on creating specialized spaces within industrial facilities, such as those used in semiconductor manufacturing or pharmaceutical production, where precision and cleanliness are paramount. Designing advanced ventilation and filtration systems, specifying materials that meet stringent cleanliness standard and ensuring the controlled condition required for the industry.

Implementation of ACMV systems is to maintain optimal indoor environmental conditions within the facility tailored to the specific requirement of industrial settings. Designing and installing systems that regulate temperature, humidity, and air quality by integrating energy-efficient solutions, providing effective climate control while minimizing environmental impact.

HT (High Tension) and LV (Low Voltage) Electrical system involves the comprehensive design, installation and maintenance of electrical systems catering to both high-tension components for larger-scale power distribution and low voltage components for everyday electrical requirements. This system includes the design of wiring layouts, distribution panels and other electrical infrastructure, ensuring the safety and efficient supply throughout the industrial facility.

To create an optimized utility infrastructure that meets the needs of industrial operations by planning and implementing the infrastructure for utilities such as water, steam, gas, and other essential services required for manufacturing process. Ensure reliable supply distribution, and efficient use of these utilities, is within our capabilities to ensure overall efficiency and functionality of the facility.

Fire protection system is design to prevent and manage fire risks within the facility. Focus on creating comprehensive solutions that safeguards both people and facility by integrating fire detection, alarm, and suppression systems. Collaborated with the authority to ensure that the fire protection system complies with the safety codes and standards.

Lorem

Lorem

Lorem

Lorem

Lorem

Lorem

Lorem

Lorem